Color Print

Highlight your logo in vivid color on bags, pens, drinkware, technology items and accessories with this decorating which includes methods such as silkscreen, transfer, and pad-print. Available in single or multi-color, it’s an economical way to gain high visibility. PCNA will choose the most appropriate method to obtain high visibility for your artwork. - Color Print Silkscreen - Color Print Pad - Color Print Offset.

Digital Print

Looking to make a bold impact with a photo or 4-color process artwork? Our methods allow fine halftones and an expanded color range to capture the sharpness of the design and then transfer it to the product. PMS matches cannot be done with 4-Color Process methods. - Digital Print Inkjet - Digital Print Transfer.

Laser

Laser engraving gives your logo a clean, distinguished appearance by precisely etching the artwork into the material’s surface. - Laser: Standard laser imprinting on metal and ceramic surfaces, including items such as pens and flash drives.

Perfect for Technical Fabrics

Applicable at virtually any location, laser produces a permanent tone-on-tone look that's great for technical fabrics. For a bold look, this method provides a beautiful mixed media look when paired with embroidery, as shown. Topical application that can be placed over seams and zippers. - Smooth finish with a glossy look. - Best for mid-range colours. - Unlimited washability. - Mixed Media* is available on select garments using laser as the base decoration beneath either embroidery or transfer for a unique look. From the very beginning of the product development cycle, our apparel is designed with decoration in mind. We understand that your brand is your business, so we work to ensure that our decoration methods - which are specifically created for our apparel - create an authentic branding experience. Our goal is to produce a finished piece that looks as though it was custom made just for you. *Mixed Media is not included in our all-in pricing model. Second-location fees apply. Mixed Media is available on select garments with a True Edge, overlay on laser.

Deboss

Deboss allows you to leave an impression of your logo in a material’s surface. Deboss utilizes a die that is heat-pressed into the material. - Deboss

Great choice for waterproof garments.

Ideal for waterproof and other technical fabrics, deboss uses a die that's heat-pressed into the material, creating a striking 3D appearance. - Applicable at virtually any location. - Subtle tone-on-tone look. - Works equally well on all colours and black and white. - Unlimited washability. - High degree of detail available. - Only works on polyester fabrics. - From the very beginning of the product development cycle, our apparel is designed with decoration in mind. We understand that your brand is your business, so we work to ensure that our decoration methods - which are specifically created for our apparel - create an authentic branding experience. Our goal is to produce a finished piece that looks as though it was custom made just for you. *Mixed Media is not included in our all-in pricing model. Second-location fees apply.

Embroidery

This traditional method of decorating material with needle and thread is a popular favorite year after year. It’s an excellent way to add value to your next promotion. All reorders up to 10,000 stitches are eligible for SureShip®. We will digitize artwork if needed but if a digitized file is provided, the setup fee is 50% off standard setup. - Embroidery

High value look

Embroidery offers thread colors to match any logo and reduces costs with up to 10,000 stitches included in the price. Classic look. - Precision-engineered production capability for exceptional detail. - Popular choice for left/right chest, left/right bicep decoration. - Mixed Media* is available on select garments using embroidery over laser. From the very beginning of the product development cycle, our apparel is designed with decoration in mind. We understand that your brand is your business, so we work to ensure that our decoration methods - which are specifically created for our apparel - create an authentic branding experience. Our goal is to produce a finished piece that looks as though it was custom made just for you. *Mixed Media is not included in our all-in pricing model. Second-location fees apply.

Epoxy Dome

Add dimension and shine to your one-, multi- or 4-color logo by placing it under a clear, high-gloss polyurethane dome with black bezel. Logos are maximized for the best possible display and then placed on a white background unless otherwise specified. Add texture, dimension or a metallic finish to your logo with our HXD decoration. This bold method brings your logo to life with modern style and 3D texture, giving your artwork a high-impact look that turns heads. - Epoxy Dome

Sublimation

Sublimation lets you decorate select hardgoods items from seam to seam with full, vibrant color. And since heat is used to infuse the ink into the fabric – rather than just sitting on top – it’s less prone to fading.

Patch

Choose from vintage or wovens. - Exceptional reproduction of detailed and complex logos or images. - Match virtually any colour. - Perfect for small complex decoration.

Transfer

Exclusive to our brand Trimark, True EdgeTM Transfer is a cutting-edge heat transfer process that provides superior clarity and precision. - Can reproduce freestanding text as small as 8 point. - Precision alternative to "sticker" or "label" appearance. - Access to locations that can't be reached with embroidery hoop, 4-colour process or spot colour. - Good alternative to embroidery for thin garments. - No contours required. - Mixed Media* is available on select garments with a True EdgeTM Transfer overlay on laser. From the very beginning of the product development cycle, our apparel is designed with decoration in mind. We understand that your brand is your business, so we work to ensure that our decoration methods - which are specifically created for our apparel - create an authentic branding experience. Our goal is to produce a finished piece that looks as though it was custom made just for you. *Mixed Media is not included in our all-in pricing model. Second-location fees apply.

inFusion

inFusion is a decorating method that seamlessly joins logos with our custom-made fabrics, creating a stylish image that is both lightweight and permanent. - Why inFusion? Lots of reasons... Endless colour possibilities with only one setup cost. Artwork is fused into the fabric, so you get the most breathable and comfortable garment possible. - Large maximum imprint dimensions and unique locations. Want your logo wrapped around the hip? On a sleeve? On the pocket? You got it. - Need it fast? inFusion orders are eligible for SureShip® so your decorated order is shipped the next day. - Specs: - Maximum logo size is 18" x 12". - Logo can cross over. - seams/zippers*. - EPS files converted to outlines is required in CMYK breakdown, no white. - Orders up to 500 pieces will be produced in 5 days from approval of proofs. Production times to be confirmed with your decorating Order Processing Specialist for quantities over 500 pieces.

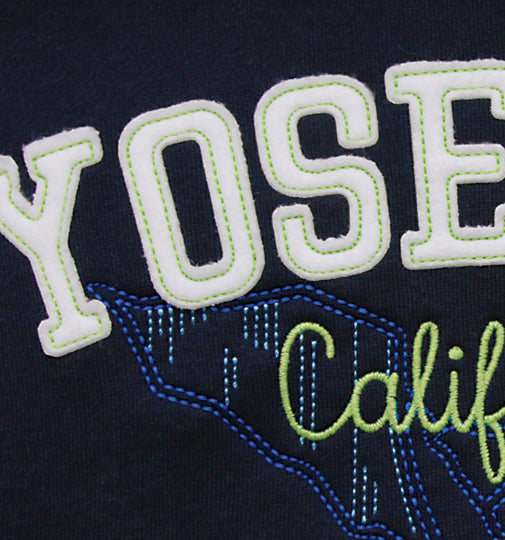

Applique

Applique provides a true vintage look that's perfect for large decoration. *Additional charges are applicable for this decoration method.

HXD

Introducing HXD, a unique branding method that creates a subtle pop from the product surface to give your logo a whole new dimension. If you're looking for what's trendy in retail, this is it. -Unique Finishes- With HXD, you can choose a standard finish, a metallic finish or even a combination of the two. *Additional charges are applicable for this decoration method.

Serigraphy

Screen printing is a printing process that involves putting ink through a woven net and transferring it to a pre-designed stencil. This technique allows for vivid colors, original patterns and sharp images. Screen printing (also known as "frame printing") is a printing technique that creates images on fabric using stencils and ink. Although the preparation time required is much longer than with digital printing or heat transfer printing, screen printing is still popular as it is the most economical mass production method. SILKSCREEN DYING PROCESS: Screen printing is a technique with a steep learning curve that requires knowledge ranging from making the screens to setting up the presses to the printing itself. CHARACTERISTICS: Vivid colors that make your images stand out Possibility of printing on a variety of materials Perfect technique for high volume orders Four-color printing Four-color printing makes your brand appear as vibrant and vivid as a photograph. The brand's four-color printing uses four basic printing colors - cyan, magenta, yellow and black (CMYK) - in fine dots in halftones. Unlike other printing techniques, the colors overlap to create thousands of shades. This technique is also called screen printing.

To bring your brand to the level that it deserves, we also offer different branding methods

360 FULL-WRAP LASER

4-COLOR PROCESS

BRANDPATCH

BRANDSHIELD

BELLY BANDS

CUSTOMIZED PACKAGING

DEBOSSED BRANDPATCH

FULL CVG 4CP FLEX TRANSFER

FULL COVERAGE DEBOSS (WITH OR WITHOUT INDENTED DOMING)

NFC

HOT STAMPED

LAMINATION

LINER PAGES

PAD PRINTED

VARIABLE DATA

MULTI-COLOR IMPRINT

All our products are also available blank

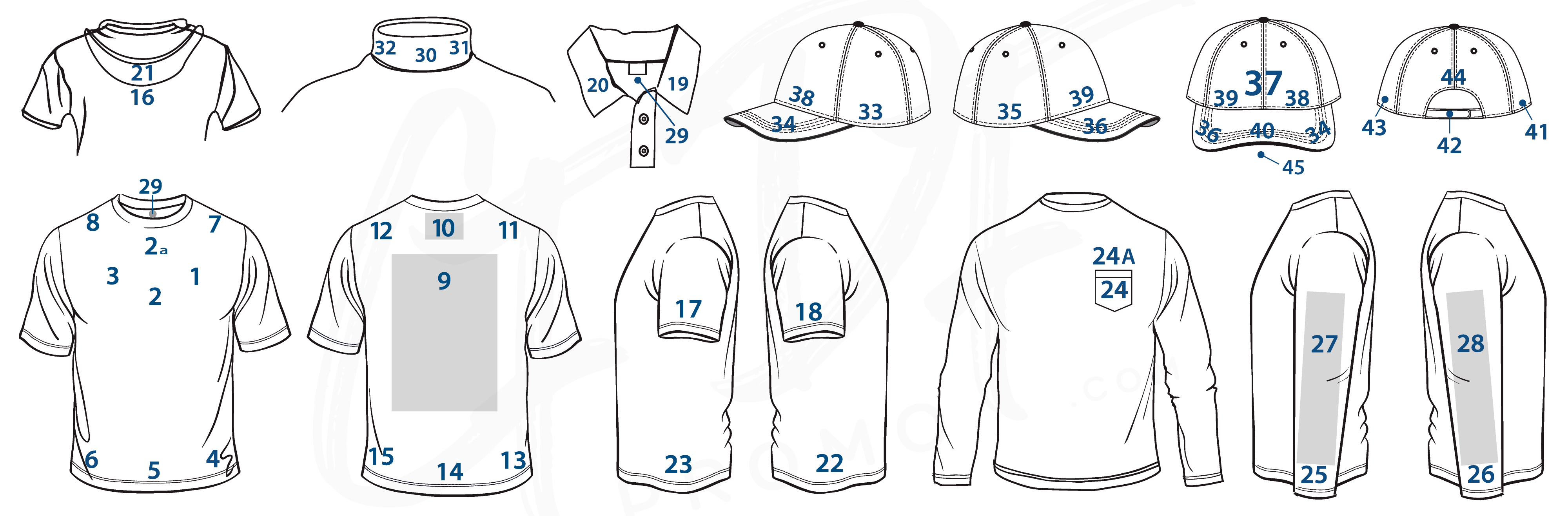

Apparel + Decoration in a Single Order

We create stylish, comfortable clothing people love to wear - and then we decorate it right here at CFDF Promo, with seven different ways to give your logo exactly the right look That means one P.O. - and half as much work - for award-winning decorated clothing.

AN ADAPTIVE SERVICE

Tell us about your project and a member of the team will be happy to find the ideal method for you.

Tell us about your project